Pioneering a sustainable future by turning waste into value in Farnham, Quebec

Nature Energy is proposing its first innovative renewable natural gas (RNG) production plant in Farnham, Quebec

Why RNG?

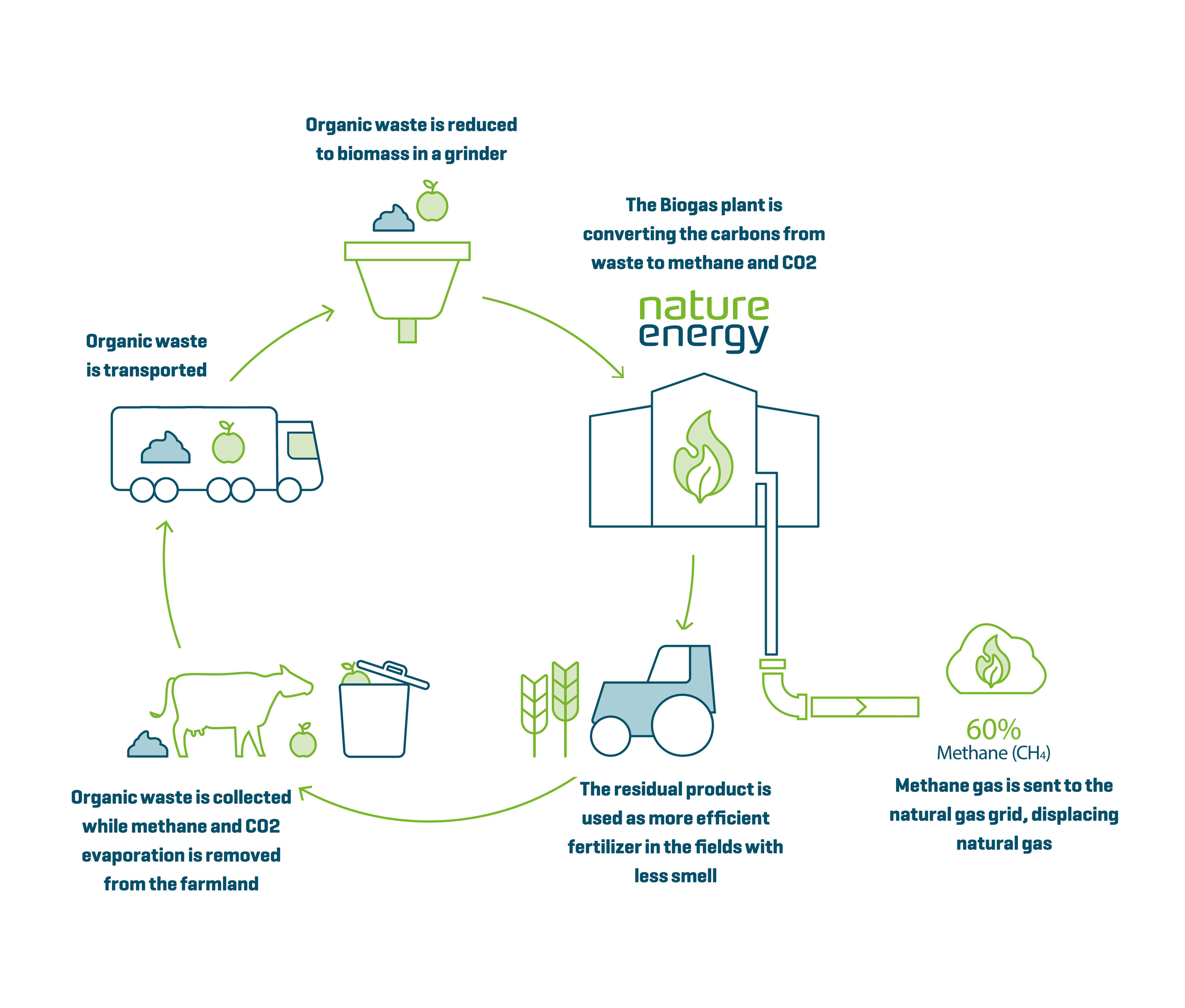

RNG, or renewable natural gas, is produced by the conversion of what we don’t want into what we need. The process transforms organic agriculture waste into climate-friendly gas, speeding up the Quebec energy transition.

What is RNG?

RNG is just like natural gas but made from organic waste. It goes directly to the gas grid and can be used for industry, ships, fuel and heating private households.

Why Farnham?

Because the region is densely populated with farms capable of providing up to 3.7 times the biomass required for the operations of a Nature Energy plant.

From animal waste to the grid

Manure and slurry naturally produce methane gas, which can be captured and converted into renewable natural gas through a biogas process.

This is a local, 100% renewable energy source that can be fed into the natural gas grid.

Nature Energy develops, builds and operates renewable natural gas (RNG) plants according to the latest principles and with advanced technology to ensure the best utilization of waste from farmers, industry and citizens.

RNG is produced by the conversion of what we don’t want into what we need. The process allows us to transform food waste, organic fertiliser and other organic waste into climate friendly gas. This enables us to solve a problem of waste in society, while at the same time creating important renewable energy that can be passed on directly to the many sectors requiring biogas in the energy transition.

The organic waste is brought to the plant and then sent to the plant’s processing tanks (digesters). In the digesters, which run at around 50 °C, bacteria convert biomasses into biogas and liquid fertiliser (digestate). Before the gas is sent to the natural gas grid, CO2 and the unpleasant toxic hydrogen sulphide are removed from the raw biogas in an upgrading unit. The gas can then be distributed as renewable energy throughout the province.

A collective project contributing to the well-being of future generations

Fostering good relations with the community

Tight odour control with negative pressure buildings.

Hiring of a local workforce.

Optimized truck routes and schedules.

Valuation of local resources and infrastructures.

Respecting the environment is central in our business model

Reduction of 60,000 tons of GHGs per year per facility.

Improvement of soil, water and air quality.

Valorization of the territory’s organic matter.